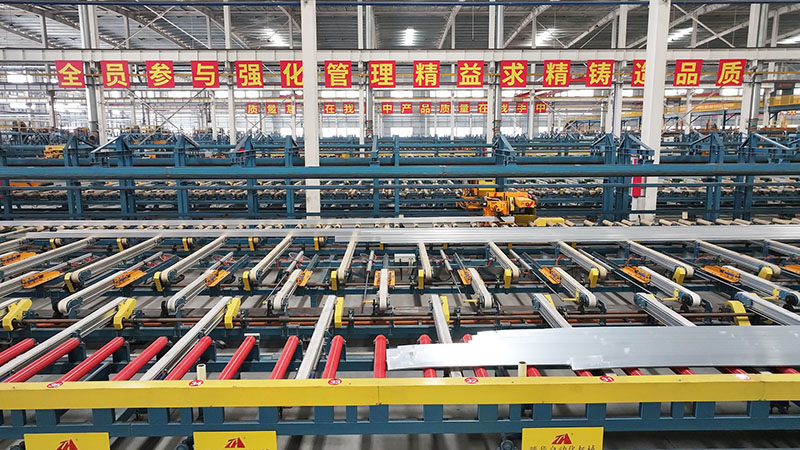

The company operates six production facilities, six industrial parks, and three service platforms.

Production Facilities: Plant No. 1, Plant No. 2, Plant No. 3, Huajian Light Alloy, Zhonghong Technology, and the Mold Center.

Industrial Parks: Huajian Innovation Park, Huajian High-Tech Park, Huajian Technology Park, Huajian Industrial Park, Huajian Agro-Ecological Park, and the Sino-European Energy-Saving Door & Window Industrial City.

Service Platforms: Huajian Hotel (hospitality services), Linqu International Convention & Exhibition Center (event hosting), and Biaozheng Inspection & Testing Center (quality control and testing).