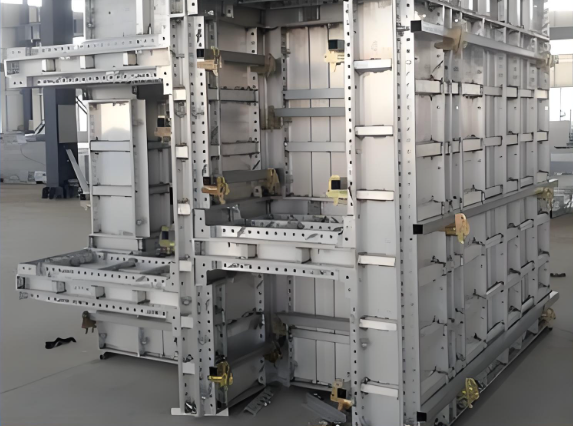

Aluminum alloy formwork, also known as concrete engineering aluminum alloy formwork, is a new generation of formwork system after plywood formwork, composite steel formwork system, steel frame wood (bamboo) plywood system, large formwork system, and early dismantling formwork system. Aluminum alloy formwork is a formwork suitable for concrete engineering, mainly made of aluminum alloy profiles and processed through mechanical processing and welding processes. It is designed with a module of 50mm and is composed of panels, ribs, main profiles, flat formwork, corner formwork, and early dismantling devices. The design and construction application of aluminum alloy formwork is an innovation in concrete engineering formwork technology, a promotion of prefabricated concrete technology, and a manifestation of the industrialization of construction technology.

Having the ability to develop aluminum alloys, we can match alloy combinations according to different performance requirements of customers, which not only meets their needs for product performance and lightweight, but also achieves cost savings.

Based on the precision and performance requirements of the product, we can independently design the production process route, which greatly improves the performance of the welded parts and ensures the dimensional accuracy of the assembly.

Having the ability to develop and modify extrusion and stamping molds, reducing mold development costs.

Having automated extrusion production lines and CNC production lines reduces labor costs.

We have advanced production lines for surface treatment such as oxidation, electrophoresis, and painting, which can meet different customer requirements while reducing equipment investment costs.

The group currently has over 150 extrusion production lines ranging from 600 to 10000 tons, with an annual production capacity of 800000 tons, of which 40% are over 2000 tons. Including various specifications of extruders ranging from 500 tons to 10000 tons, the Sixth Factory is mainly dedicated to the production of industrial profiles and automotive lightweight profiles, with sufficient production capacity to meet customers' extrusion needs of various sizes and specifications.

We have established a national level standardized testing center, which has been accredited by the China National Accreditation Service for Conformity Assessment (CNAS) and accredited by the China National Accreditation Service for Conformity Assessment (CMA); There are 13 high standard laboratories jointly established, including chemical analysis laboratory, metallographic laboratory, mechanical performance laboratory, physical performance laboratory, spectroscopy laboratory, salt spray laboratory, and aging laboratory. Key instruments and equipment are imported from countries such as the United States, Germany, and Israel.

The aluminum extrusion experience of the group has a development history of more than 20 years. After years of verification and accumulation, a rich database of data and experience has been formed, including product databases, design standards, analysis specifications DFMEA、PFMEA、 Control plan, process validation data, etc.