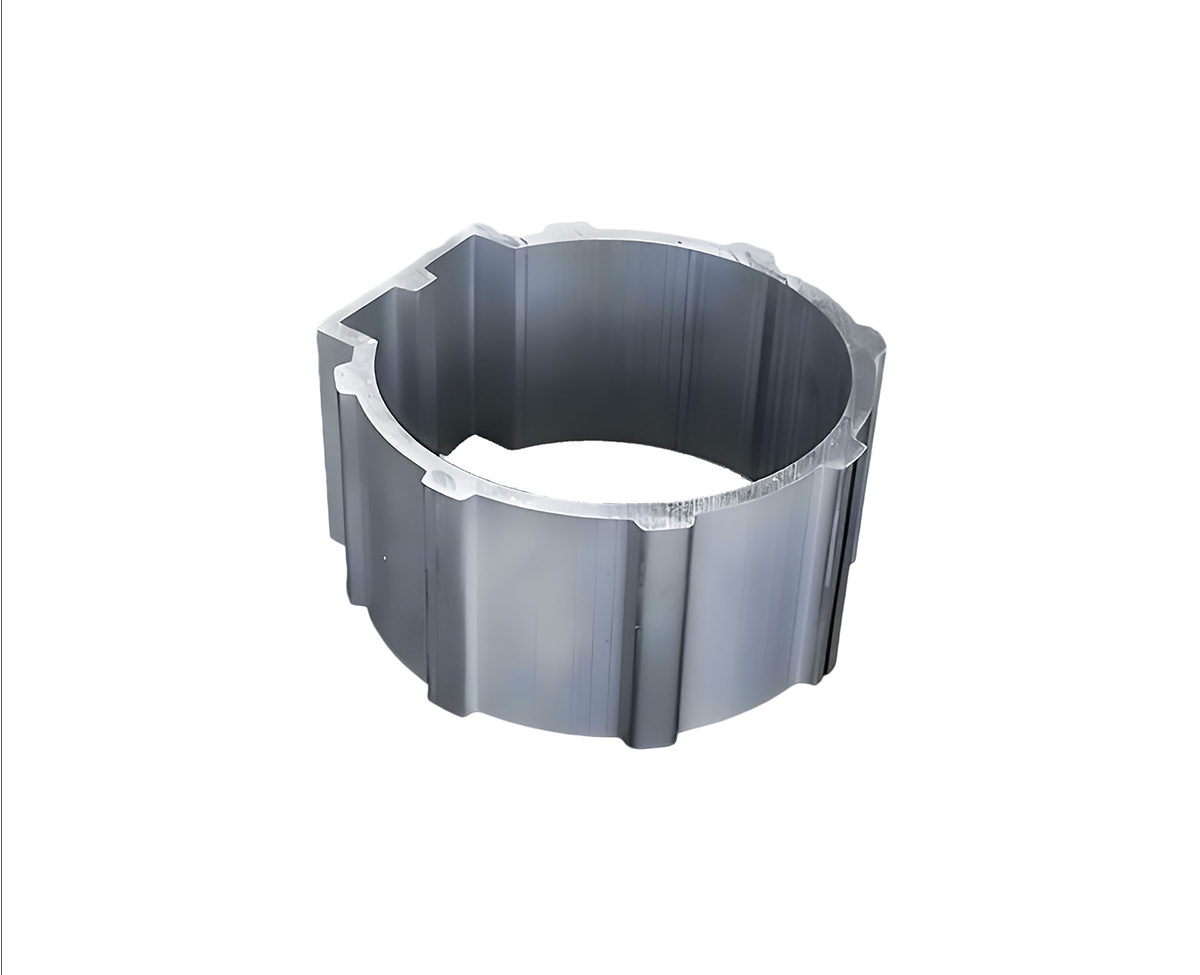

The high-pressure shell is a structure used to protect internal components from external environmental influences, and may also need to withstand certain internal pressures. It is made of pressure resistant materials and can provide good sealing and structural strength. Widely used in urban power grid construction and renovation projects, industrial and mining enterprises, high-rise buildings, and public facilities, as a ring network power supply unit and terminal equipment, it plays a role in the distribution and control of electrical energy and the protection of electrical equipment. It can also be installed in box type substations.

·Huajian Aluminum Industry has mature 6 series and 7 series aluminum alloy formula technology, which can customize high-strength, high toughness, and corrosion-resistant aluminum alloy materials

·Through strict casting process control and composition analysis, ensure stable material properties and suitability for long-term use in high-pressure environments.

·Capable of designing large tonnage extruders and precision molds, capable of producing high-strength profiles with complex cross-sections, reducing welding joints, and improving the overall integrity of the shell.

·High thermal conductivity and heat dissipation performance, quickly dissipate motor heat, and extend service life

·Lightweight design reduces the overall weight of the equipment

·High strength, high pressure resistance, impact resistance, and deformation resistance

·Control the inner diameter size, concentricity, and waterway size to ensure the accuracy of the deep processing process

·Small tolerance control ensures precise fit with internal components of the motor

·Maintenance free, wear-resistant, and lower overall cost

·The inner diameter size can be 34mm-406mm

·Provide accessories such as waterway blockage and heat dissipation plugs

Having the ability to develop aluminum alloys, we can match alloy combinations according to different performance requirements of customers, which not only meets their needs for product performance and lightweight, but also achieves cost savings.

Based on the precision and performance requirements of the product, we can independently design the production process route, which greatly improves the performance of the welded parts and ensures the dimensional accuracy of the assembly.

Having the ability to develop and modify extrusion and stamping molds, reducing mold development costs.

Having automated extrusion production lines and CNC production lines reduces labor costs.

We have advanced production lines for surface treatment such as oxidation, electrophoresis, and painting, which can meet different customer requirements while reducing equipment investment costs.

The group currently has over 150 extrusion production lines ranging from 600 to 10000 tons, with an annual production capacity of 800000 tons, of which 40% are over 2000 tons. Including various specifications of extruders ranging from 500 tons to 10000 tons, the Sixth Factory is mainly dedicated to the production of industrial profiles and automotive lightweight profiles, with sufficient production capacity to meet customers' extrusion needs of various sizes and specifications.

We have established a national level standardized testing center, which has been accredited by the China National Accreditation Service for Conformity Assessment (CNAS) and accredited by the China National Accreditation Service for Conformity Assessment (CMA); There are 13 high standard laboratories jointly established, including chemical analysis laboratory, metallographic laboratory, mechanical performance laboratory, physical performance laboratory, spectroscopy laboratory, salt spray laboratory, and aging laboratory. Key instruments and equipment are imported from countries such as the United States, Germany, and Israel.

The aluminum extrusion experience of the group has a development history of more than 20 years. After years of verification and accumulation, a rich database of data and experience has been formed, including product databases, design standards, analysis specifications DFMEA、PFMEA、 Control plan, process validation data, etc.